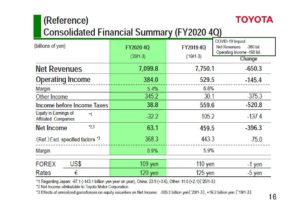

Tokyo, Japan, May 12, 2020―Toyota Motor Corporation (TMC) announced its financial results for the fiscal year ended March 31, 2020 in a press conference today.

“Become stronger together with our partners throughout the world”

(Remarks by President Akio Toyoda at Financial Results for FY2020)

- Toyota’s corporate composition (Comparison with the time of the global financial crisis)

Hello everyone.

Today, based on our financial results and forecast, I would like to share with you my thoughts on how Toyota intends to confront the COVID-19 crisis.

Since my appointment as president in 2009, Toyota has faced numerous crises. In overcoming them, I believe that our company has been able to gradually strengthen its corporate composition.

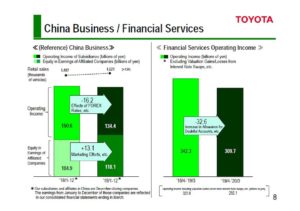

Please have a look at the changes in our earnings structure from just before the global financial crisis, to the present.

- The three years to March 2008 (The three years just before the global financial crisis)

In the three years just before the global financial crisis, while operating income increased due to favorable exchange rates and increased vehicle sales, our earnings structure excluding the effect of foreign exchange rates was not good by any means due to a large increase in fixed costs.

I think that was a period during which the speed of expanding the size of the company was faster than that of developing our people, which partly led to our recall crisis later.

- The year to March 2009 (The year immediately after the start of the global financial crisis)

In the year immediately after the start of the global financial crisis, vehicle sales decreased by 1.35 million units, for a year-on-year decrease of approximately 15 percent, to which was added the impact of the strong yen, resulting in our falling 461 billion yen into the red.

- The four years to March 2013 (The first four years after becoming president)

The four years just after I became president was a time when our entire company faced an overwhelming need to respond and unite to overcome numerous crises, such as the global financial crisis, the massive recall crisis, the Great East Japan Earthquake, flooding in Thailand, and the so-called “Six Hardships” in Japan, including an ultrahigh yen.

Over these four years, we were able to bring the number of vehicles sold back up to the levels we had before the global financial crisis.

At the same time, by drastically reducing R&D expenses and capital expenditures, we were able to shrink our fixed costs, and, despite the ultrahigh yen of an exchange rate of 83 yen to the dollar, we achieved an operating income of 1.3208 trillion yen.

However, because we stopped everything to stop the bleeding, including investing in the future, we ended up still needing some time to strengthen our company composition in a true sense.

It was a period in which we lost weight and became slim but also lost necessary muscle.

- The seven years to March 2020 (The last 7 years)

In the most recent seven years, our fixed costs increased due to investment for accelerating the making of ever-better cars and due to investments in response to CASE. However, it was a period in which we strengthened our composition while absorbing the costs of these investments through such means as cost reduction.

In the first three of those years, although we aimed to strengthen our true competitiveness during what we called an “intentional pause”, my self-assessment was that I was not able to obtain sufficient results.

Our “intentional pause” made me keenly feel the difficulty of carrying out reforms in normal times.

At last year’s financial results announcement, I was asked if Toyota faces any challenges, and I replied: “The fact that there is a sense within the company that Toyota is doing fine.”

There was a consciousness, which had taken hold over many long years, within the company that Toyota was doing fine, and there was a corporate climate in which things were thought about based on that premise. I sense that what led me to earnestly engage in reforming these things was my own “intentional pause.”

With a once-in-a-century period of profound transformation coming on top of that, over the past few years, we came to feverishly engage in both “a fight to bring back what makes us Toyota” and “completely redesigning Toyota for the future.”

During that period, as we believed that management would have to change first to change the company in an uncharted era, we took various measures to fundamentally revise our executive and organizational structure, including the introduction of an in-house company system, establishment of our “Seven Samurai” (the president and six executive vice presidents) structure, and discontinuance of the post of executive vice president.

Our revisions covered not only people actively filling posts but also our advisor system.

When it came to communicating with our employees, such as during labor consultations in the spring, we made genuine efforts to achieve true mutual understanding.

Labor and management at Toyota share a common foundation of “the company hopes for the happiness of its employees, and the labor union hopes for the growth of the company.” In this period of profound transformation, earnestly hoping for the happiness of our employees, we decided to further address hitherto common practices, such as raising base wages and implementing uniform wage increases, and the company and labor union are holding thorough discussions as part of striving to fundamentally reform how we work.

Each time such a reform has been carried out, I have heard people both inside and outside the company say: “You don’t have to go that far.” I have even been told that I was over-instilling others with a sense of crisis.

Even so, I have continued on because I want to be able to pass the baton to the next generation in a way that I consider ideal. That is my ardent wish.

I think that “bringing back what it is that makes us Toyota” is equal to spending time on the past. I want my generation to be the last to spend time on the past. I want the next generation to be able to spend time on the future. That’s exactly why I hope to plant seeds for the future. This is what I consider to be the ideal way to pass the baton to the next generation.

Based on this desire, for the future, I have been actively advancing the building of partnerships through alliances.

We have also changed our company’s thinking about alliances.

Our basic stance is that alliances are not for taking control of partners based on the logic of capital, but rather for respecting each other and for cooperating through work with like-minded partners.

As a result, within an extremely short period of time, we have been able to establish a network with many partners, including those from other industries.

When it comes to cooperation within the Toyota Group, based on our new “home & away” strategy, we have largely changed our thinking from becoming strong as an individual company to becoming strong together as a group.

Also, with undergoing a “complete redesign” into a mobility company in mind, we are also engaged in recomposing our assets, such as by revising our cross-shareholdings and selling underutilized real estate.

Summarizing our initiatives over the past several years, I think I can say that we have freed ourselves from a hitherto theory and are constructing a theory for a new Toyota in a new era.

- The year to March 2021 (Battling the COVID-19 crisis)

And now I would like to touch on our forecast for the year to March 2021.

In the current COVID-19 crisis, although we forecast a decrease in vehicle sales of 1.95 million units, for a year-on-year decrease of more than 20 percent, which would be greater than the decrease during the global financial crisis, we forecast a profit, with an operating income of 500 billion yen.

Although this is our forecast at this time, if we are somehow able to achieve this level of our earnings, I believe that it would be the result of our having been able to strengthen our corporate composition.

- The meaning of a system for domestic production of 3 million vehicles

From now, I would like to talk about something that Toyota has insisted on and committed to for many years.

I am referring to defending to the very last our system for domestic production of 3 million vehicles a year.

This is not something that is meant to only have to do with Japan.

Toyota plants in Japan have served as mother plants that support Toyota’s global production. It can be said that Toyota’s domestic production system is the foundation for a global Toyota.

However, this is not something simply left up to fate, nor is it something that can be taken for granted.

Based on our conviction that we need monozukuri (making things, or manufacturing) and a place to hone competitiveness that can drive global production in Japan, we have, indeed, held fast at all costs to protect our domestic production, no matter how severe the economic environment has been, including the ultrahigh yen.

We did this not only to protect Toyota but also to protect the enormous related supply chains and the jobs of the people involved, as well as the fundamental technologies of Japan’s automotive industry and the human resources who have the skills to support such technologies.

Along with COVID-19, people around the world are facing a state of not being able to get what is needed when it is needed.

There was a person who called this situation the “mask phenomenon.” According to such person, most face masks could not be procured in Japan.

“Making better products at a lower cost.” This is the foundation of monozukuri. However, I think that only aiming to make something at a lower cost can give rise to this kind of phenomenon.

There is another basic element to monozukuri. It is: “Making things means making people.”

People are not costs. People are the source of continuous improvement and a driving force for the growth and development of monozukuri.

As COVID-19 infections spread, many monozukuri companies have started to produce medical face shields and protective gowns, as well as masks and other items.

We, too, are making medical face shields in the United States using 3D printers, and we have extended such efforts to other parts of the world, including in Japan and Europe.

Furthermore, when it comes to items that we cannot produce on our own, such as ventilators, we are providing support by applying TPS to improve productivity.

I believe we can do these things because we have insisted on having a system for domestic production of 3 million vehicles, and because we have preserved monozukuri in Japan.

What we have been defending to the very last has not been “3 million vehicles.”

What we have been continuing to protect have been people who have acquired the techniques and skills that enable them to make what is necessary when the world needs it.

We are proud that we have been continuing to protect in Japan places in which such human resources can work and be cultivated.

Even as we are now facing the COVID-19 crisis, there is not the slightest bit of distortion or wavering in this belief.

That said, however, there is something that I ask everyone to understand. To continue to protect a certain thing and to keep doing what we are doing is by no means easy.

I sense that there seems to be much talk about a v-shaped turnaround. Sacrificing employment… Sacrificing domestic monozukuri… By deciding to “Stop” various things, an individual company can turn its results around.

Far from being criticized, it bothers me that such action often seems to be praised. “That’s not right.” This is how I feel.

Regardless of how big or how small they might be, there are many companies in Japan that have clenched their jaws and protected their human resources who had techniques and skills, no matter how tough times were, or, more importantly, because times were tough.

I believe that now is exactly the time that we need a society that can support such companies. I humbly request that you support companies that have supported Japan and Japan’s economy through monozukuri.

Disclaimer

Toyota Motor Corporation published this content on 12 May 2020 and is solely responsible for the information contained therein